In the project for the new Caru laboratory, emphasis has been placed on develop a kind of state of exception capable of reconciling technological development and sustainability, giving the architectural form a recognizable and unique visibility. This project to update the idea of a “rational use” and expresses it in the language of contemporary architecture, translating it as sustainability.

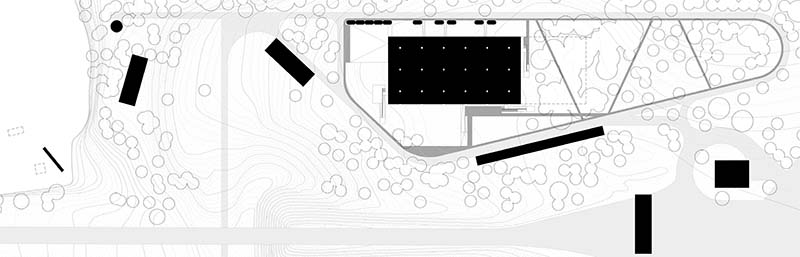

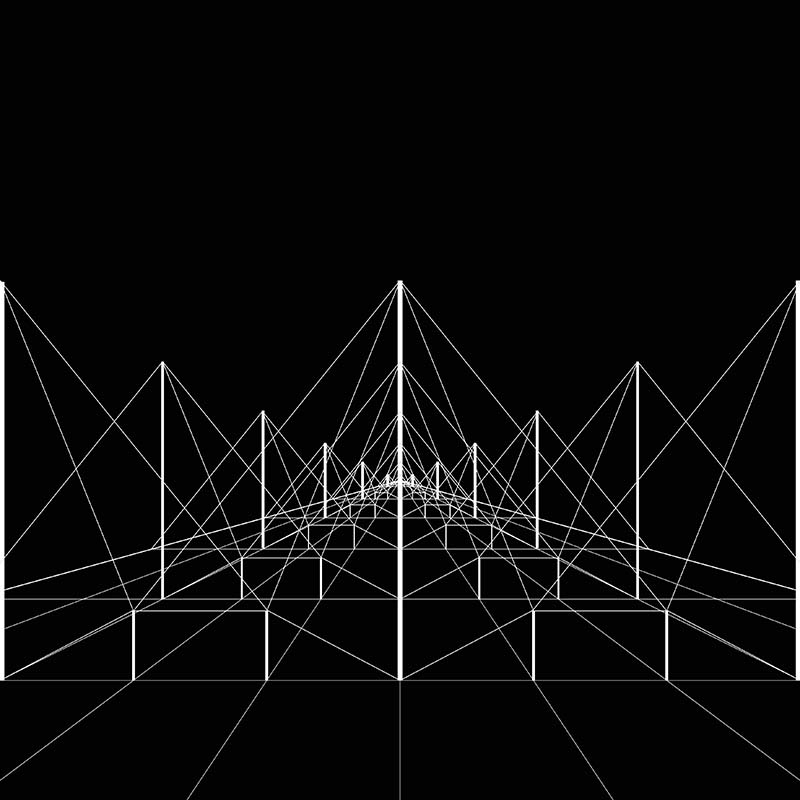

The design seeks to minimize any sense of intrusion into the place and maximize its role as an identifiable sign in the landscape. The building is recognizable from a distance and establishes a direct dialogue with the scale and direction of the bridge infrastructure, highlighting its character as a technological object. The position adopted reduces deforestation and the raised ground floor of the laboratory allows the surface runoff to remain uninterrupted with slight modifications to the terrain. The surplus soil excavated during construction is used to create a strictly controlled landscaping.

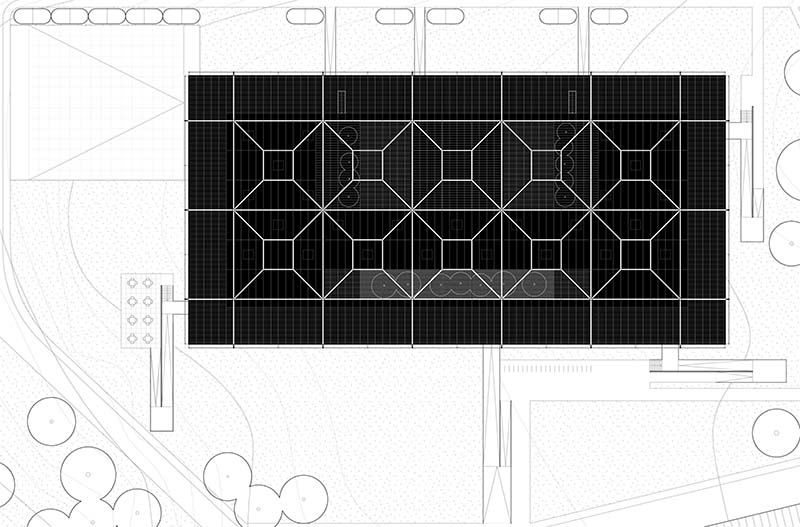

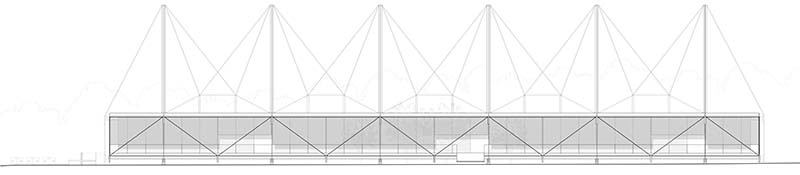

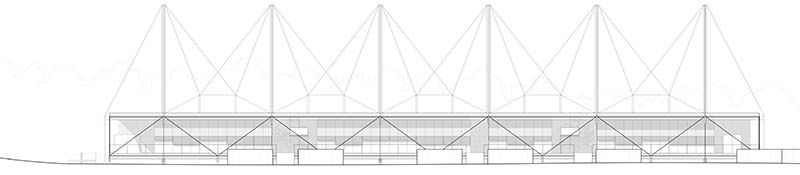

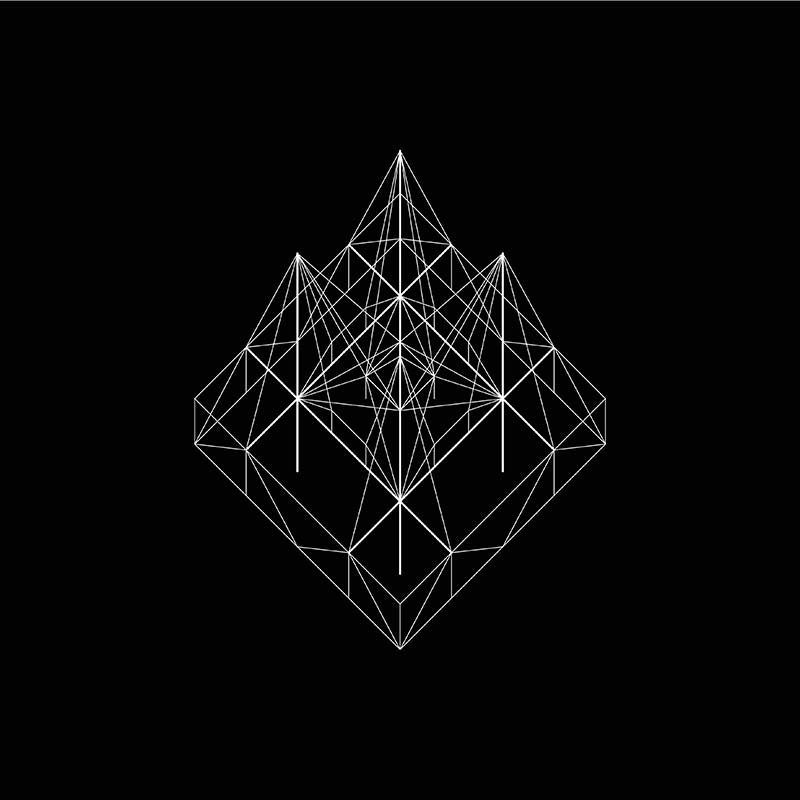

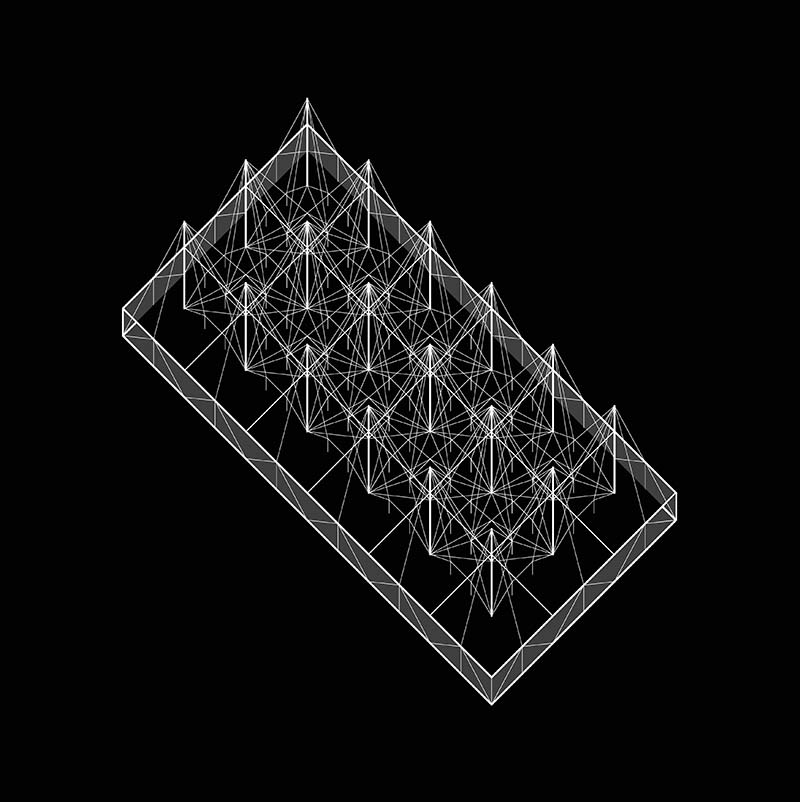

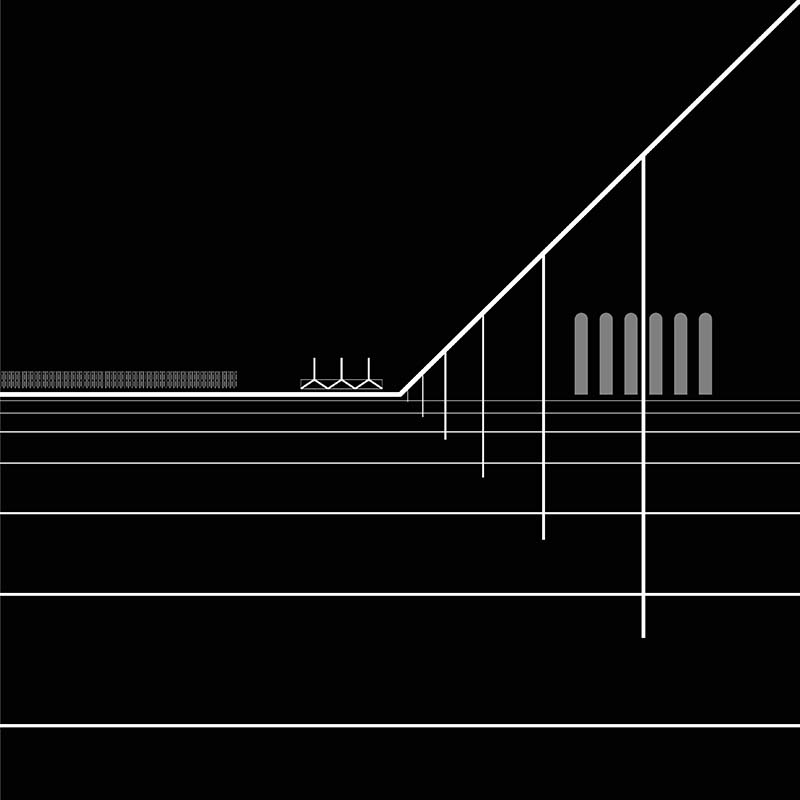

The main building is located in a clear area at the east of the plot ,between heights 18.50 20.00, with an implantation parallel to the axis of the bridge. Its cable-stayed metal structure rises 14.40 above the suspended roof of the building that covers a continuous ground floor, raised above the ground, at elevation 20.85.

The structural elements visible from the international bridge and the various technical conditioning devices build the thermodynamic beauty of the technological object. Devices such as chimneys, vents, photovoltaic membrane, etc. are an integral part of the architectural design. Larger installations such as HVAC equipment, potable water and fire tanks are placed in a pit on the deck, under a metal louver.

A series of auxiliary constructions surround the main building, absorbing those functions that are incompatible with laboratory work, such as the various waste deposits, the deposit of flammable supplies and the analytical gases area. The satellite condition of these constructions increases the safety and the laboratory operation quality, making these service elements as part of the architectural design.

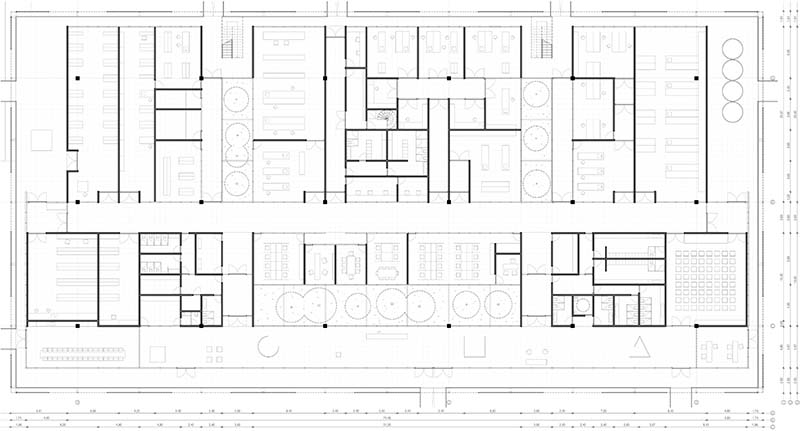

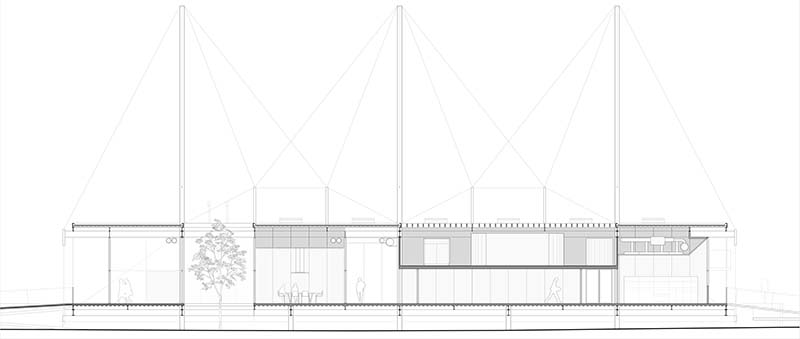

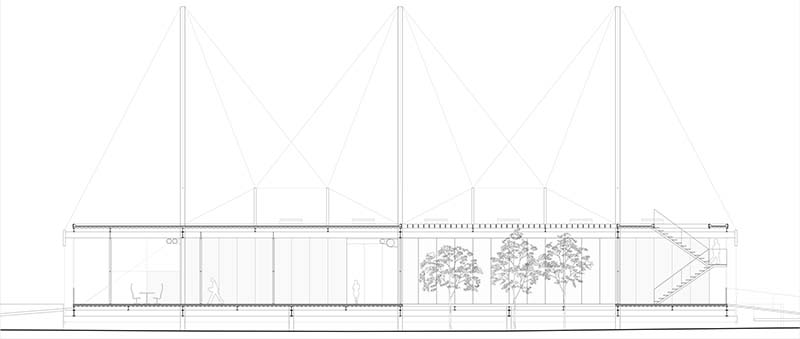

The building consists of an extensive plant, in which courtyards are opened allowing natural lighting and ventilation; the only spatial obstruction is the rigid structure of the engine room that centralizes the routes of the installations suspended under the roof. This configuration produce a flexible and transformable building, with an important contribution of natural conditioning and a characterization of the spaces given by natural light.

Three programmatic bands organize the different functions of the building in areas with a specific spatial image.

The first constitutes an open space located to the west and open to the bridge. At one end the dining room is incorporated, which takes the model of a refectory with a single table, overlooking the river and at the other, the general administration near the entrance. Between the two, access is expanded in the “Area of Environmental Interpretation of the Uruguay River”, a space for disseminating the research and monitoring tasks carried out, which will transmit experiences and values that promote knowledge and environmental conservation of the River in society.

The second is divided into three sectors and includes at the center, the main courtyard and all the scientific offices that are attached to it. On both sides, the services of the complex are arranged, and at its ends, to the south the auditorium open to the first band and to the north the deposits of field equipment and supplies linked to the esplanade and the circulation of the laboratory.

The third band opens to the trees located to the east of the site, and includes the two remaining courtyards and the engine room in the center. The laboratories are arranged to the south, and the sampling areas to the north linked to the esplanade.

The circulation scheme combines the comb structure for the laboratory, the linear one for the area open to the public and independent secondary circulations for the services. An external perimeter circulation allows maintenance tasks to be carried out without affecting the operation of the building.

A modulation based on a 120×120 design module and its multiples is proposed; a minimum constructive module of 60 coinciding with the dimension of the ceiling panel of the laboratories and a maximum of 1440×1440 coinciding with the structure.

The structure facilitates the incorporation of new conditioning systems and deep restructuring of the internal organization. Besides this, the structural connections allow a future extension avoiding the interruption of the use.

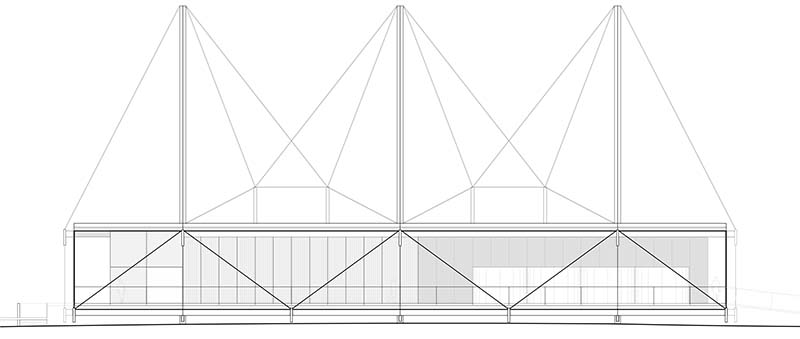

The suspended metal skeleton of the laboratory is recognizable from a distance, its 1440 masts allow the arrangement of a network of tie rods from which the beams hang. This solution decreases drastically the total weight of the building, freeing the lower face of the roof for a flexible distribution of services and facilities, while the raised lights ensure an almost total transformation capacity.

The 86.4m by 43.2m structure is resolved based on 18 masts with a square section, 40 cm on each side, forming an orthogonal grid, with 6 pillars in the longitudinal direction, 3 in the transverse direction and a 720 in cantilever. the perimeter.

It consists of elements that require very little manufacturing and are easily joined. The joints between the column and the beam starter are made in the workshop, reducing the transport length of the section, facilitating its installation. The rest of the bolted joints result in a higher execution speed. The joints between jointed beams and masts allow great constructive simplicity and the possibility of regulating the tension of the cables, controlling the level of stress on the beams.

The structure can take well the dimensional changes associated with the thermal variations of the site, due to the low internal hyperstaticity and due to the mechanical characteristics of the steel. Expansion joints are not contemplated.