A neighbourhood icon with multiple programs

The Microlibrary Warak Kayu is the fifth built project within the Microlibrary series – an initiative to increase reading interest by creating socially-performative multifunctional community spaces with environmentally-conscious design and materials, which aim to serve low-income neighbourhoods. Designed by SHAU and prefabricated by PT Kayu Lapis Indonesia, this project is a community, private sector and government collaboration – a gift from Arkatama Isvara Foundation to the City of Semarang. The microlibrary charges no entry fee and is run by Harvey Center – a locally-embedded charity group in Semarang – in coordination with the local government.

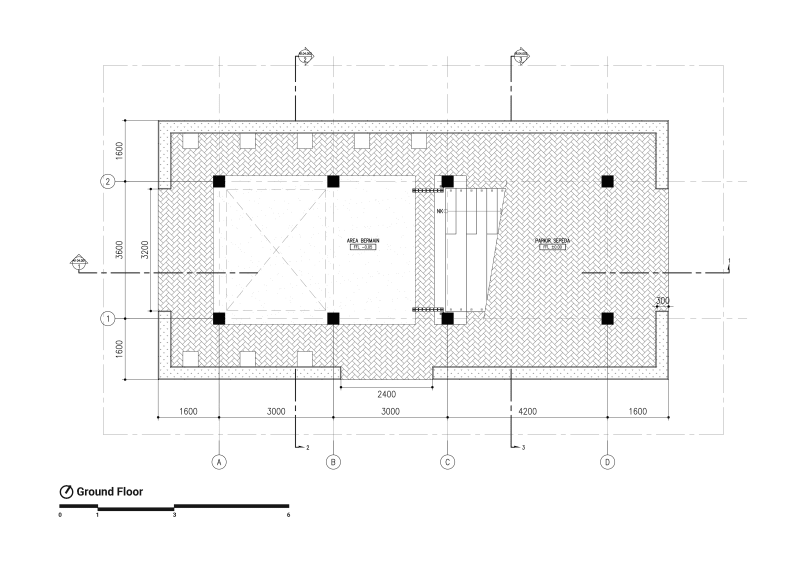

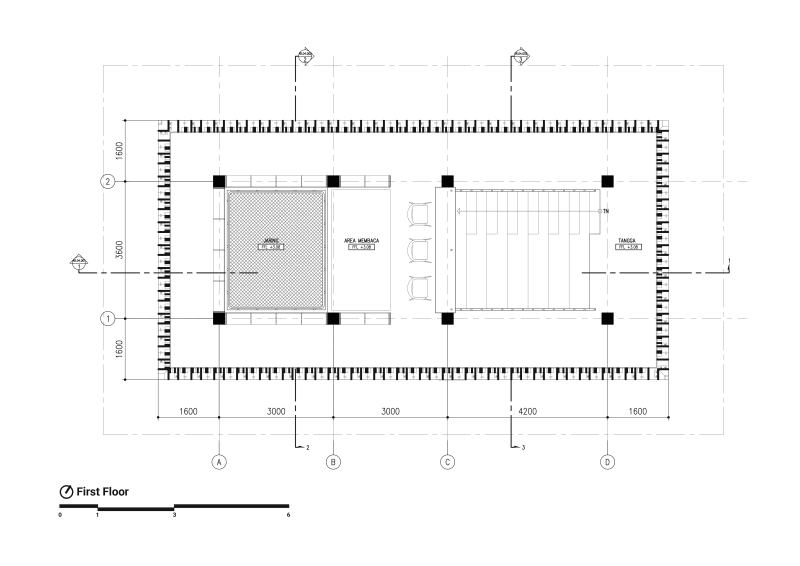

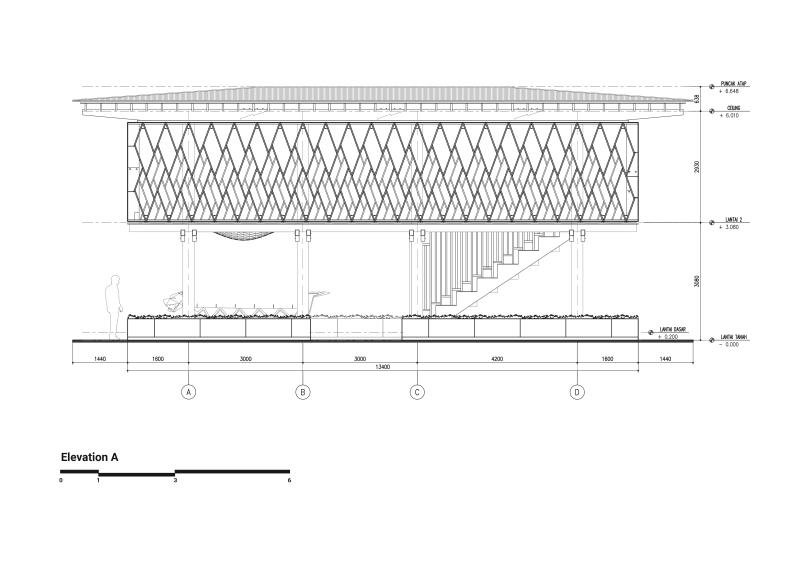

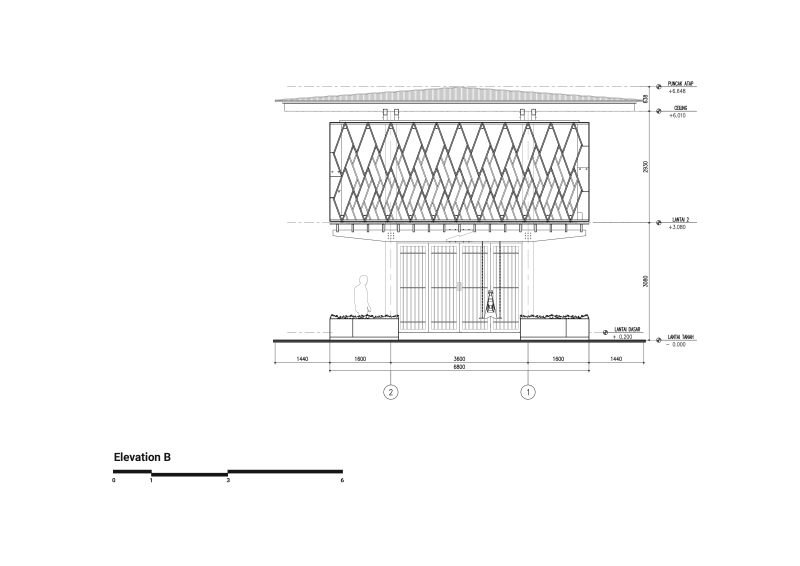

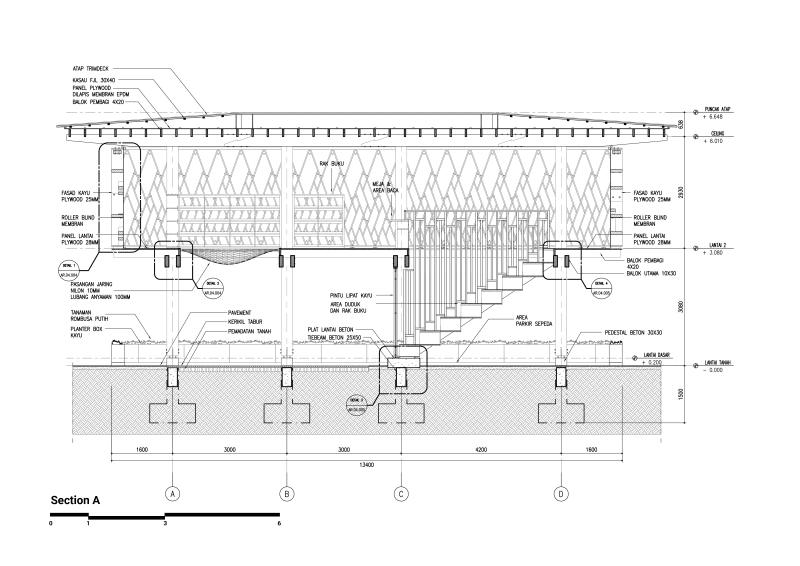

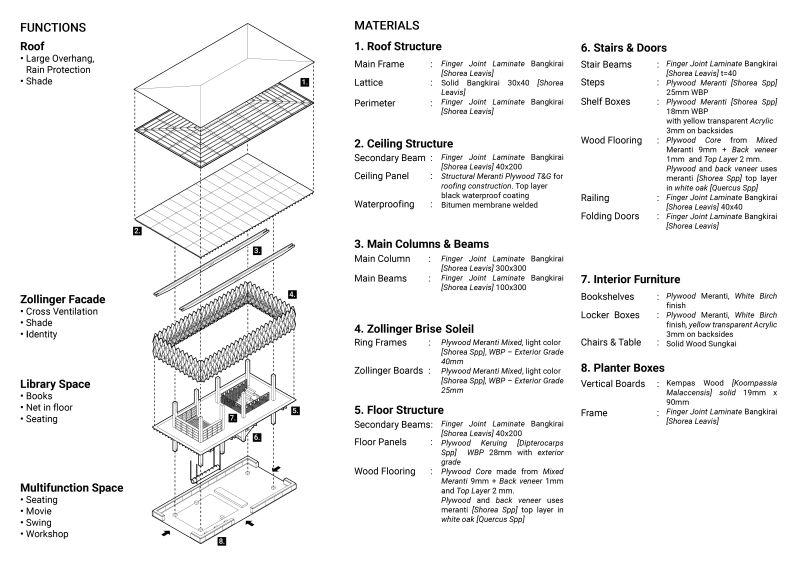

Architecturally it represents SHAU’s passive climate design, material and typology experimentation for the tropical context. After numerous design iterations, the most favorable design concept was the one with the whole building being elevated, like a traditional ‘rumah panggung’ (house on stilts) because it does not only function as library but adds value by becoming a neighborhood and community center, at the same time being used to promote Indonesian engineered wood products and manufacturing capabilities. By elevating the library, various spatial configurations, multiple programs and a wide range of activities can be offered. On the ground, is a large semi outdoor area which can be used for workshops, as well as a wide tribune seating at the entrance for watching presentations or movies, and to grab the kids’ attention: a wooden swing. The ground area is framed by a ring of planter boxes to create a more intimate atmosphere. Upstairs in the library itself, there is a net where kids can lie down, relax and read but also directly communicate with parents and friends in the space underneath. It is important to have this multi-programmatic approach to make the library a popular place, since reading alone is not yet considered a fun activity in the country.

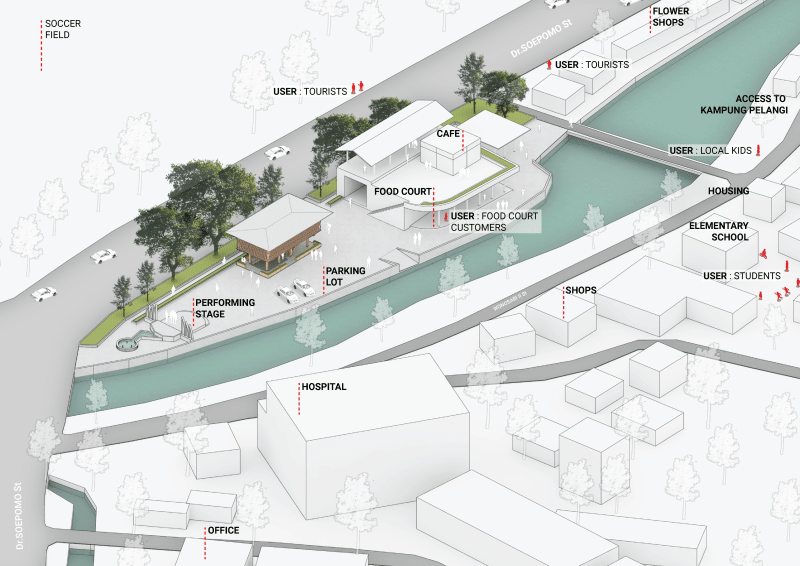

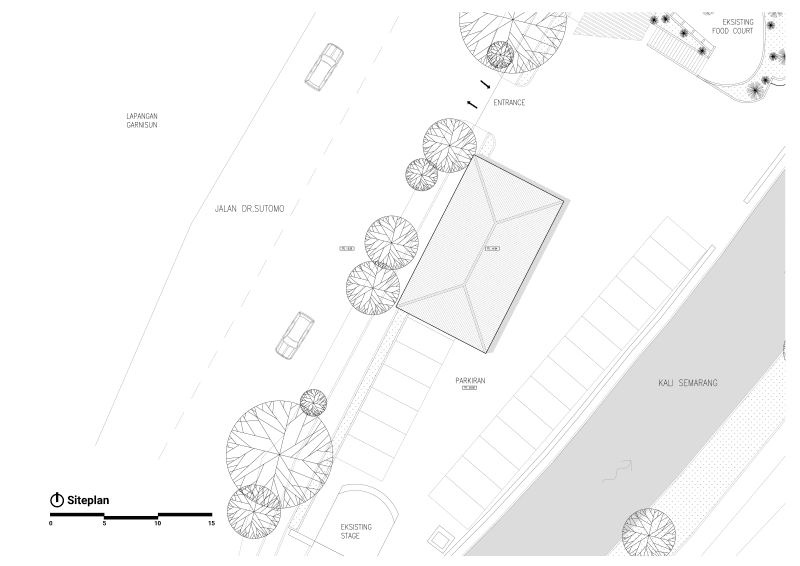

The Microlibrary Warak Kayu is the latest addition to the iconic architecture landscape of Semarang, the capital of Central Java in Indonesia. It is built at Taman Kasmaran, a public square in the city center with direct proximity with a river and has a great view to Kampung Pelangi (Rainbow Village- a local tourist attraction). The square has a cafeteria with warungs (small vendors) underneath and there is a local school nearby. The current mayor of Semarang – Hendrar Prihadi – has already announced in public his enthusiasm on the new library. It will be part of the city’s tourism route where the free bus tour will stop. In that sense the library serves not only the local neighborhood but is embedded in the larger city network and thus has an increased reach.

The first library in Indonesia entirely made of FSC-certified wood

The building could be seen as a living educational spot for wood material and construction techniques. All wood materials in the building are entirely FSC-certified. This is possible thanks to the donor and client, Arkatama Isvara Foundation, which has strong relationship with PT Kayu Lapis Indonesia, an integrated wood manufacturing company. A great variety of their available materials and products for construction are used and only foundation, footings and roof cladding are not wood-based materials.

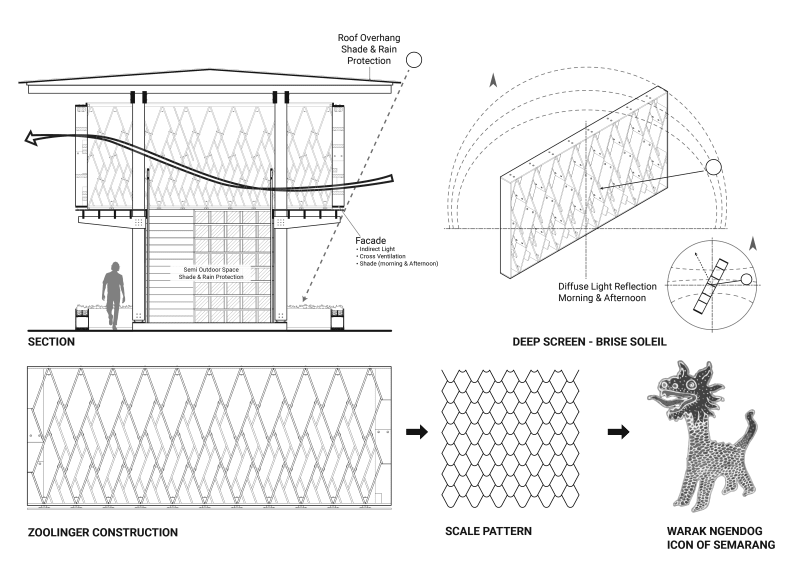

The design process includes a bottom-up process, where all available products in the factory were first evaluated, and the design was developed from that. As one of the design exploration results, the brise soleil was based on the ‘Zollinger Bauweise’ a construction system which was developed in the 1920’s in Germany. It is a form of reciprocal system, resulting in a distinctive slightly shifted diamond pattern. This pattern happens to resemble a local mythical creature ‘Warak Ngendog’ and its dragon-like skin, displayed during annual festivals in Semarang. Hence the name Warak Kayu in Indonesian – meaning Wooden Warak, which is a positive narrative for communicating the design to a wider audience.

Environmental performances: climate design, material & construction

The Microlibrary Warak Kayu is designed around passive climatic design aspects: no air conditioning is used, therefore no energy is spent. Semarang has a Tropical Monsoon Climate according to Köppen climate classification with temperatures up to 34 degrees Celsius during the end of dry season. The building is cooled down by means of cross ventilation and solar heat is prevented from entering using shading elements. The roof overhang provides shading around noon. The longer facades are oriented North-West and South-East due to site restrictions. Therefore, an egg-crate like deep screen – Zollinger brise soleil is designed to block the lower sun altitude angles in the mornings and afternoons. That means direct sunlight cannot enter the building in an unobstructed way. As a result, the diffuse-reflected sunlight is sufficient to read books without artificial lighting. In addition, the depth requirement of the Zollinger brise soleil was determined by the angular relationship between the sun path and building rotation. The cross-ventilation aspect also helps to drag the moisture out of the building and prevents books from getting moldy or damaged.

Wood as construction material outperforms many other materials regarding embodied energy, water and air pollution, carbon footprint, and it is also a re-growing material. For the Microlibrary Warak Kayu all wood materials are in compliance to the SVLK (Indonesian Legal Wood) and FSC (Forest Stewardship Council) certification. Wood is sustainably logged in Central Kalimantan, then shipped from Sampit over the Java Sea southwards to Semarang (Java) and the factory. The whole process also includes nursery, replanting and harvesting time planning to maintain sustainability for the coming years.

Various types of wood products and wood species were used. For the main structural components like columns and beams Bangkirai-based FJL (Finger Joint Laminate) was used. For decking and the Zollinger Brise Soleil different Meranti-based plywood types in various thicknesses were employed. A complete material list is provided in the diagram.

The main structure of columns, beams and secondary beams has the highest volume of all materials. Here only Bangkirai – a tropical hard wood with high weather resistance often used for outdoor furniture and decks – is used. The byproducts of this manufacturing in form of leftover and small-cut wood pieces are trimmed and processed for finger joint strip elements. That means, the whole structural elements also make use of factory leftovers.

Apart from the concrete foundation all wooden elements are prefabricated at the factory in Semarang and then transported within 20 km to the site. Prefabrication of the elements at the factory, on-time delivery and on-site assembly means less noise, dust and generally less harmful impacts on direct environment during assembly and at the same time, faster construction time. In addition, with prefabrication at the factory, due to better trained workers, modern tools, higher safety standards, a safer construction process but also higher degree of precision is reached and with that less mistakes are made; which in return produces less waste. In general, wooden waste material produced at the factory can be collected more easily because no sorting is needed. Also, there is basically no distance involved in transporting waste for recycling and valuable leftovers from cutting can be used for other products consisting of smaller pieces also made at the factory. The construction of the main structural elements uses a mixture of engineered connections and carpenter joints – most notably scarf joints – for prolonging the main beams due to manufacturing practicality.